As first step, the designer’s inputs are being taken into consideration and a technical briefing establishes the cornerstones of the project and concept development.

Thanks to 3D models, rendering activity and light plans, all the technical aspects are analyzed. Materials, light sources, lighting studies and continuous researches are the key to obtain a harmonious and qualified project.

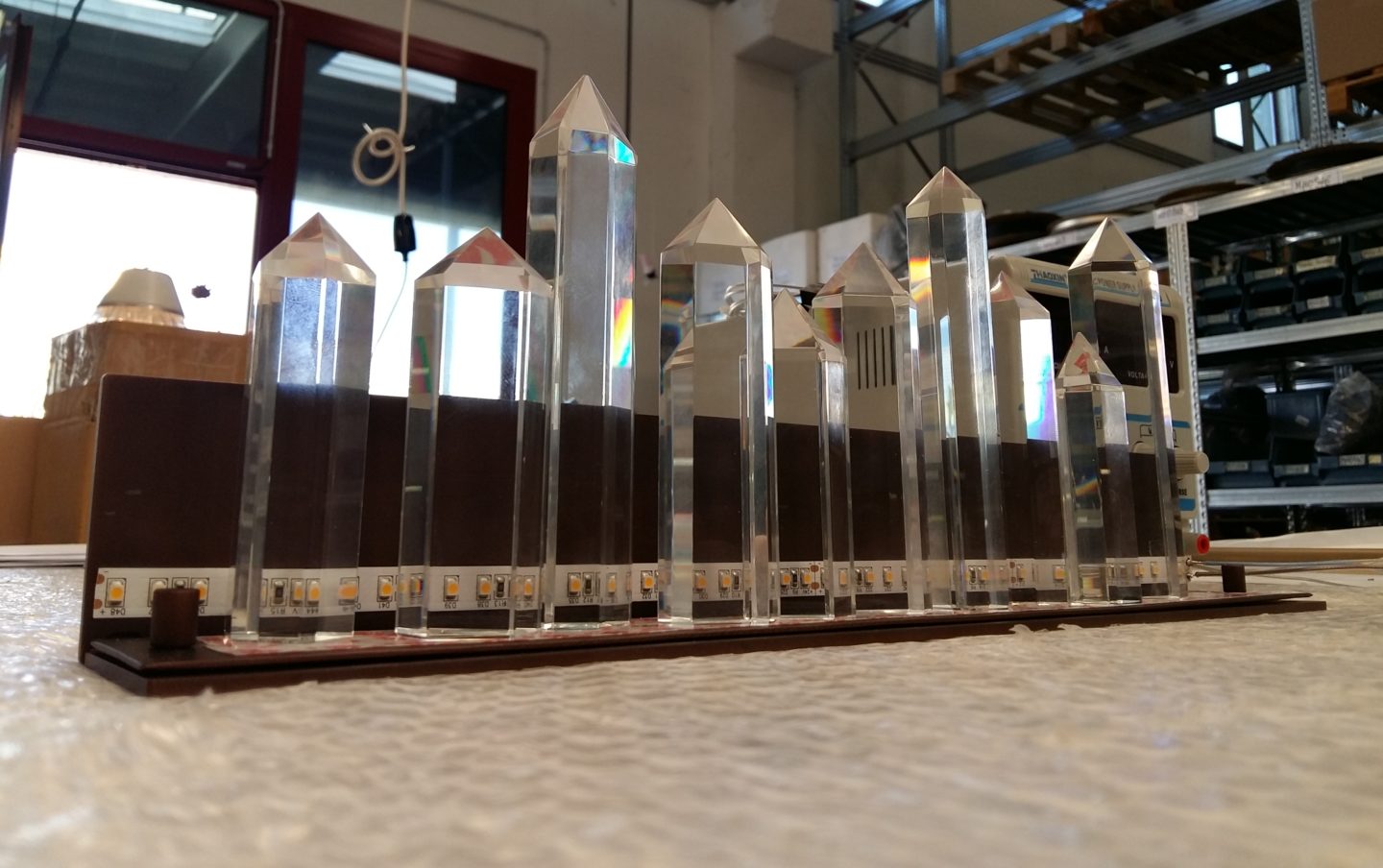

The creation of a sample is essential to see first-hand the real object, check the first sensations on the design and look of the product and the areas of improvement.

After prototyping, every product is being engineered to improve efficiency and meet the production needs to replicate each single piece with the same quality.

True craftsmen with precision, dexterity and experience create high-quality items, supported by laser cutting technology, milling, turning, bending, welding, polishing, galvanic plating, lacquering processes.

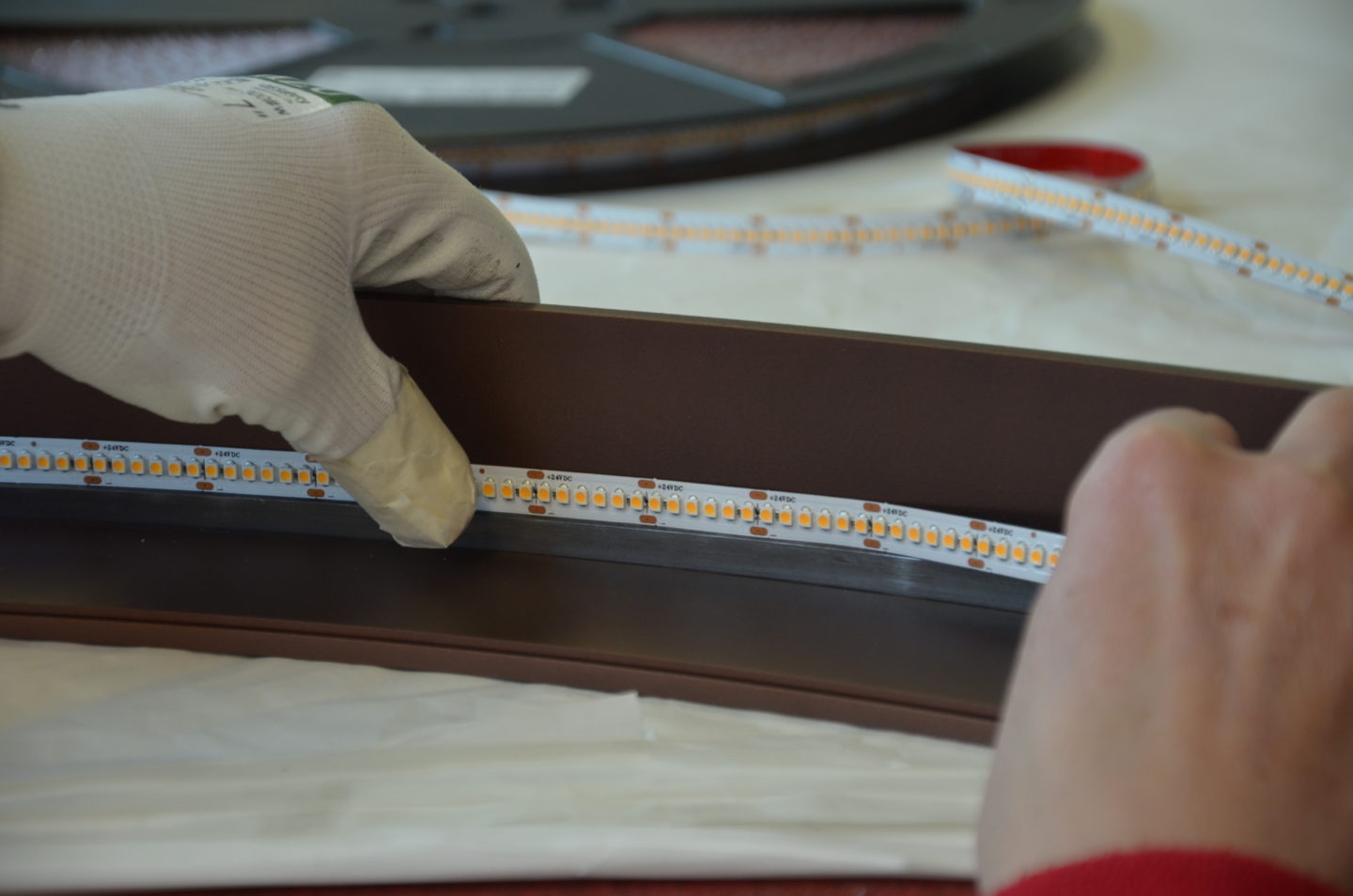

Expert hands complete the assembly of electrical and mechanical parts with precision, accuracy and attention, thanks to defined production processes. Adaptability and flexibility are primary to find effective solutions and manufacture high-standard products.

A multistage control process checks each production phase. Raw material, components, assembled parts and all the manufacturing steps are verified from the first selection, until the finished item. We care about the end-user satisfaction and are aware of the importance of details.

All products are being tested to ensure safety and compliance with the electrical and mechanical standards. Each item is recorded and identified to have full traceability of information and to ensure durability.

Packaging solutions suitable for different markets, products and materials. Customized on customer’s request. Storage services, logistics management, documentation, customs and worldwide triangulations.

We trust in true partnership with guarantee of long-term monitoring and after-sales service in order to establish strong relationship with our customers.